What is Flute?

How do you know which flute size to choose?

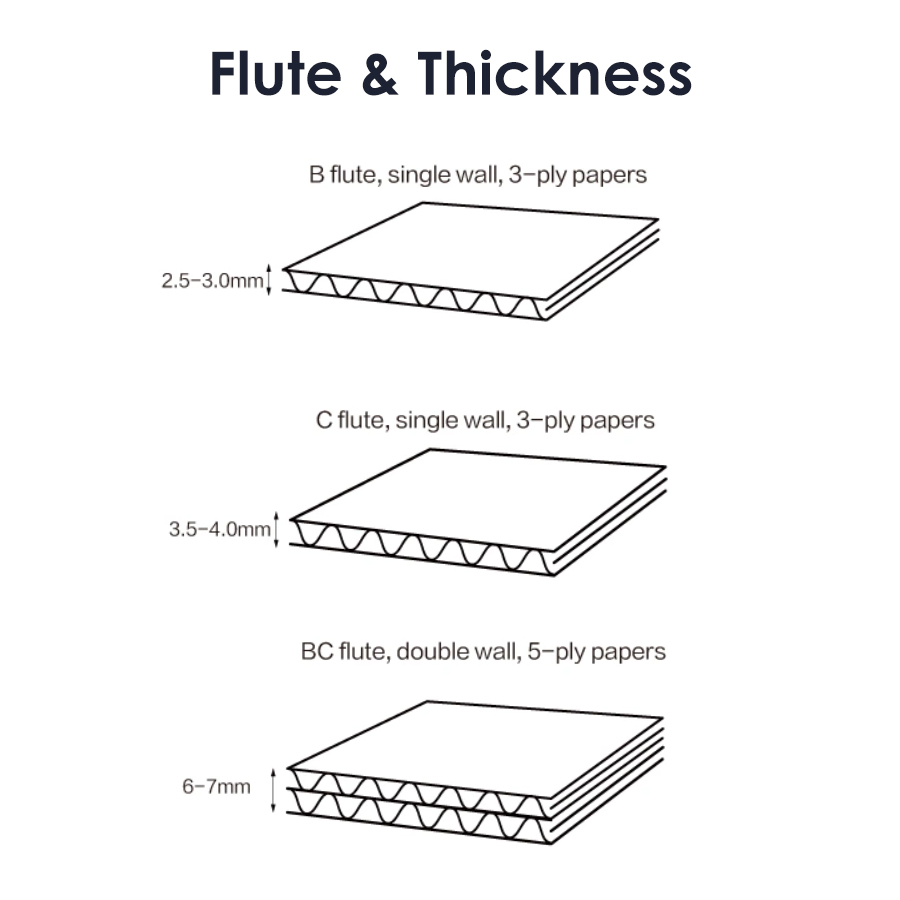

B-Flute is a 1/8 inch thick corrugated material. It is a flatter and smoother surface, so it is best used for high quality printing and die cutting. B-flute offers excellent puncture and crush resistant properties, and consumes less warehouse space. Developed for packaging canned goods, B-flute is used for beverage trays, wrap-around blanks, glass-to-glass packs, and slipsheets.

C-Flute is a 3/16 inch thick corrugated material. C-flute is the most widely used flute size, commonly used for shipping cases. Often used for packaging glass products, dairy products, and furniture, C-flute offers good crushing resistance, good stacking strength, and highly acceptable printing properties.

BC-Flute is another double-walled material, but this time combining B flute and C flute. It’s one of the thickest flute profiles 1/4-5/16, and as a result one of the most durable, offering great cushioning and stacking strength. This is great for sending heavy items or stacking shipping boxes, but may not be the best option if branding is your priority.

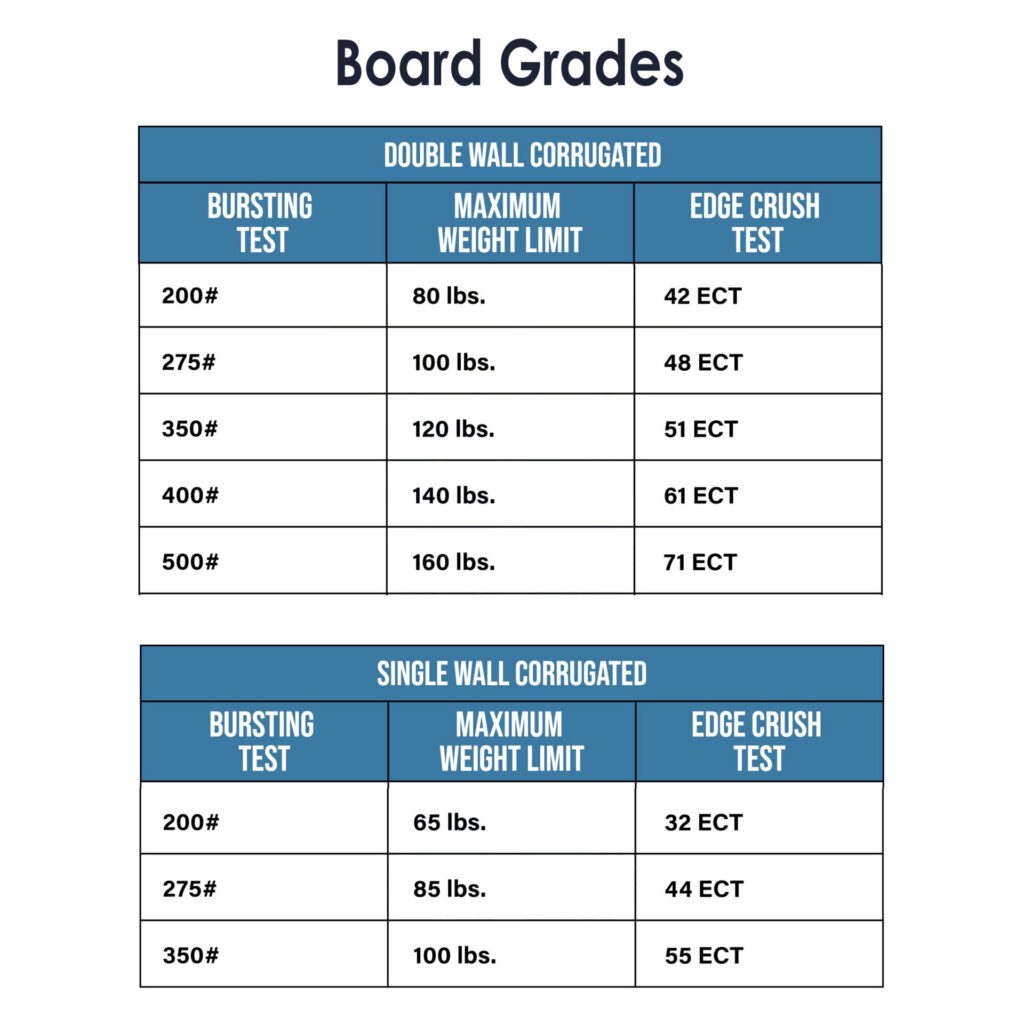

What is Board Grade (Strength)?

A corrugated box’s ability to withstand external and internal pressure is measured in a laboratory using an evaluation method called the Edge Crush Test (ECT). You can figure out exactly how much weight can be carried in a box by referring to its ECT score.

The standard corrugated moving box has an ECT score of 32, which translates to a maximum carrying-weight of 40 lbs. More heavy-duty options, like double-walled corrugated boxes (which contain two layers of fluting), have an ECT score of 48, which means they can carry up to 80 lbs of weight. Thus, ECT score matters the most after you choose the perfect corrugated box for it’s contents.